For the current manufacturing industry in domestic and abroad, intelligent manufacturing is undoubtedly the general trend of the industry development, more and more manufacturing enterprises have achieved a certain degree of automation transformation. However, in fact, the transformation of most small and medium-sized manufacturing enterprises is still slow, which leads to the lack of systematic monitoring of production process, data lag, low accuracy, long response time for emergencies, and low work efficiency.

Intelligent dashboard SOP

In response to the above problems in the production process, intelligent dashboard SOP (standard operating procedures) has gradually been favored by many small and medium-sized manufacturing enterprises. By refining, quantifying and optimizing the manufacturing-related operation steps as much as possible, the degree of refinement, quantification, and optimization is that everyone can understand under normal conditions without ambiguity.

In the manufacturing process, the intelligent dashboard is divided into many categories, including in-process dashboard, signal dashboard, inter-process station dashboard, external order dashboard, temporary dashboard, etc. Through the relevance of touch display equipment, the whole production process is connected in real-time information to ensure the standardization of operation, and make the production standard and quality analysis data more transparent, so as to ensure the product quality and improve the production efficiency.

The solution of video SOP for workshop workbench

In the application of intelligent electronic dashboard, touch display equipment plays an indispensable role as a visual display device of production data/image. Taking one of the workshop applications of Jawest's customer as an example, let's take a look at the user's requirements for the touch display equipment.

1) Application products: Jawest fourth generation of industrial all in one panel PC.

2) Product requirement points:

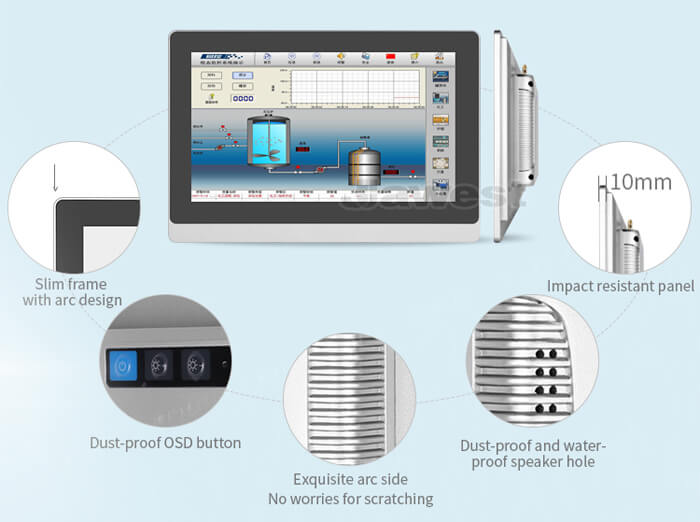

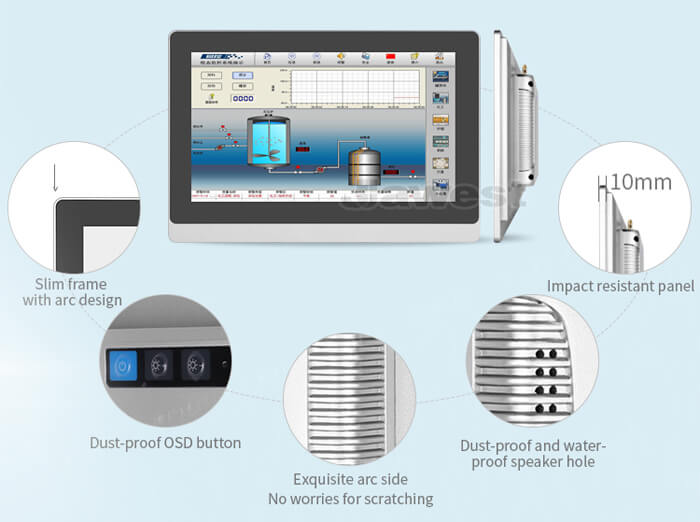

·The appearance of this four-generation industrial-grade all-in-one PC is upgraded comprehensively, and offering a strong intelligent experience. The fuselage is made of aluminum alloy, with high quality, and strong anti-corrosion performance.

·The thickness of the front bezel is 10mm, and built-in some waterproof strips. The true flat panel is IP65 level dustproof and waterproof performance.

·The front panel adopts a narrow frame design, which provides a wide perspective, simplifies the interface setting, and is easy to operate.

·Capacitive touch mode with 10-point touch technology is more suitable for the electronic dashboard, response time is less than 5ms, and multiple output mode operations is more convenient.

·Built in Windows 7 operating system, optional Windows 8 / 10, Linux operating system, software compatibility is strong.

·Intel Celeron J1900 quad-core 64-bit CPU, and 2GB for the DDR3 memory, 32GB SSD, peak frequency is 2GHz, high efficiency, and no jamming. It supports 7 * 24h barrier-free and stable operation, and upgraded i3 / i5 / i7 configurations are available to meet the different needs of users.

·In terms of the interface, in addition to meeting the general interface requirements, Jawest all-in-one computer also supports connect to the keyboard, mouse and other output devices to meet multiple needs of the workstation such as connecting the printer and attendance machine and so on.

· Jawest industrial all-in-one computer plays the role of the dashboard in the workplace supports HDMI, VGA high-definition signal input, 4K high-definition video decoding, the image display color is bright, ensure manufacturing process teaching video playback, restore high-definition details, and standardize the production operation of technical personnel.

3) Application benefits:

1. The technology and experience accumulated by the enterprise can be recorded in the standard documents through the SOP function of the all-in-one computer, so as to avoid the loss of technology due to the resignation of technical stuff.

2. After short-term training, the operators have the ability to master more advanced and reasonable operation technology quickly.

3. According to the SOP operation standard on the dashboard, it is easy to trace the causes of defective products.

4. Establish a good production image and obtain customers' trust and satisfaction.

5. Carry out the concrete embodiment of the core of ISO spirit, realize the standardization of production management, the systematization, standardization, visualization, and simplification of the production process.

6. The dashboard is an important way for enterprises to standardize production process operation, monitor product manufacturing processing, and improve production efficiency.

·For the installation method, end-users tend to choose VESA (cantilever) installation, which saves working space and is convenient to move.