In the industrial automation field, due to the industrial attribute requirements, many applications and scenarios need to carry out voltage and current frequency conversion and adjustment to meet the power supply requirements of the corresponding equipment, which promotes the frequency converter appear in many industrial sites scenarios. Among them, as the common industrial application equipment, the frequency conversion control cabinet is mainly used to adjust the working frequency of all kinds of equipment, reduce energy consumption, start the equipment smoothly, and reduce the damage of large current to the motor when the equipment is directly started.

In the frequency conversion cabinet, the control display panel, as a piece of important equipment for displaying and collecting the cabinet voltage value, current value, output power, loss power, variable frequency, and other numerical values, is also the main source for the operator to monitor the normal operation of the equipment. Therefore, in the frequency conversion control cabinet, the selection of the display panel is particularly important.

According to the requirements of scene use, touch control and display devices such as industrial all-in-one panel PC, industrial Android all-in-one tablet PC, industrial monitor, etc. are widely used in industrial cabinets. In the frequency conversion control cabinet, the requirements of the all-in-one panel PC and the industrial monitor are determined according to the user's actual scene.

Here takes the application of Jawest industrial monitor in a frequency conversion control cabinet as an example, let's take a look at the user's requirements in the frequency conversion control application scenario!

1) Application product: Jawest 15.6-inch upgraded 2nd-GEN industrial monitor.

2) Product features

1. The upgraded 2nd-GEN series industrial monitor is specially designed for industrial intelligent automation applications, offers reliable performance in harsh industrial sites.

2. It adopts aluminum alloy wire drawing technology, which makes the structure more durable and has better heat dissipation and corrosion resistance.

3. The thickness of the front bezel is only 3mm, with a built-in waterproof strip, it is embedded into the cabinet with a seamless fit and more elegant. The front panel is up to IP65 level dustproof and waterproof, which effectively avoids the cabinet failure caused by the dust entering the internal components and damaging them.

4. The operation interface of the industrial monitor is simple, and the start and stop control functions of the frequency conversion control can be marked in detail, which is convenient for the operator to control the operation of the frequency conversion device and easy to use.

5. The monitor is equipped with a self-developed industrial-grade drive board, it has more stable performance, higher cost performance, and stronger compatibility, and meets the user demand of cabinet running for a long time.

6. Due to the strong electromagnetic interference in the use scene of frequency conversion control, the capacitance and resistance screen can not avoid electromagnetic interference, so the non-touch industrial monitors are more popular with users, which can avoid the strong electromagnetic interference affecting the normal operation of the equipment.

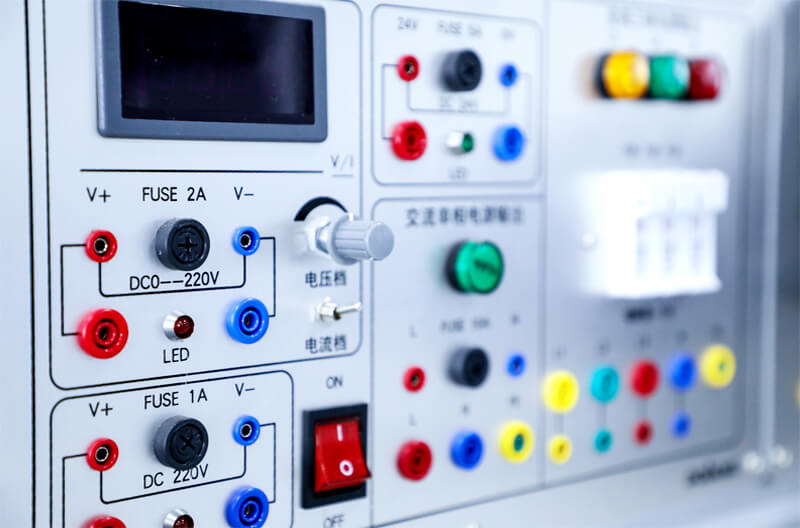

·The industrial monitor provides abundant I/O interfaces and supports a variety of external control functions of the frequency conversion cabinet. Various control buttons and indicators can be installed on the frequency conversion cabinet panel according to the system conditions, such as forward rotation, reverse rotation, motor speed increase, motor deceleration, jog forward rotation, jog reverse rotation, manual/automatic, emergency stop, frequency conversion/power frequency, PLC control, touch screen, etc.

7. The industrial-grade monitor can be connected with the voltmeter, ammeter, frequency meter, and various indicator lights, such as power indicator, alarm indicator, operation indicator, and power frequency indicator. It can realize the data monitoring of input voltage, output current, output frequency, and various working conditions of the frequency converter.

8. ODM/OEM customized services are available to meet customers’ specific requirements, such as screen upgrade, interface expansion, and other personalized services.

3) Application benefit

The frequency conversion control cabinet equipped with the industrial monitor connects the potentiometer for frequency conversion and speed regulation. According to the output frequency of the operator, the command signal can be transmitted to the motor to control the speed of the motor. At the same time, the industrial monitor is connected with the electrical components inside the frequency conversion control cabinet, which can visually display the operation status of the frequency conversion control cabinet, and it's easy for the operator to control the operation of the frequency conversion device, as well as the field operation of the motor and other controlled equipment.

4) Application expansion

The inverter control cabinet can be widely used in pumps, fans, compressors, rolling mills, injection molding machines, belt conveyors and other medium voltage motor equipment in metallurgy, chemical industry, petroleum, water supply, mining, building materials, motor industry, etc., which promotes the application scenario of industrial monitors widely used.