A screen printing machine is a kind of printing machine, which is used to print words and images. It is mainly used in the field of product packaging and printing. Its function is to leak solder paste or patch adhesive onto the PCB pad through the screen. At present, the screen printing machines on the market can be divided into vertical screen printing machines, inclined arm screen printing machines, rotary screen printing machines, four-column screen printing machines, and automatic screen printing machines.

The screen printing machine is mainly used in the electronic processing industry, mainly used for the screen marking of the printed circuit board, the sign of instrument shell panel, the solder paste printing in the process of circuit board processing. According to the type of printing, it can be divided into packaging printing, advertising printing, circuit printing, handicraft printing, and so on. At the same time, with the rapid growth of the emerging screen printing field, such as CD, anti-counterfeiting printing, the application demand for screen printing machines is also growing.

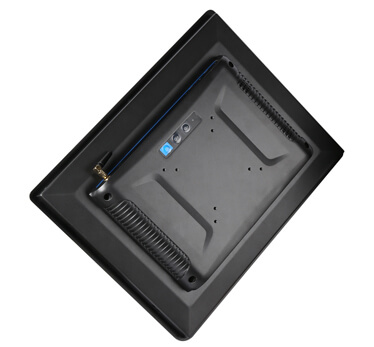

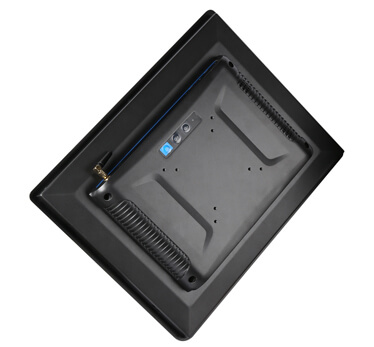

As we can see from the above figure, the touch all-in-one panel PC, as the control and display center of the whole equipment, plays an indispensable role. Through the all-in-one panel PC, the NC servo motor can be connected, and the printing, ink return, speed, distance, quantity, and other programming can be set at will so that the screen printing machine can be fully automated and the error rate of manual operation can be reduced.

Next, let's taking the application of Jawest's products applies to the screen printing machine as an example, customers pay more attention to the installation mode, operating system, working temperature, corrosion resistance and other performance of the touch screen panel PC.

In the screen printing machine application scenario, Jawest's second -generation of the industrial computer is suitable in this case. As a product series specially built for the embedded installation system, it supports seamless embedded into the screen printing equipment. In addition, the surface frame of this Jawest industrial touch panel PC is made of aluminum alloy, which has stronger corrosion resistance and meets the needs of some equipment with acidic printing materials.

Industrial touchscreen PCs mostly adopt Windows operating system to optimize the human-computer interface control interface, which is simple and easy to use; the resistance/capacitance touch screen technology is optional, while for the general normal working environment, capacitive touch is more suitable, the touch response is more sensitive, and the operation experience is stronger. However, in some special printing raw materials or harsh use environments, such as full of dust and oil stains, it is more appropriate to use a resistive touch screen.

Configuration of this Jawest second-generation industrial panel PC adopts Intel Celeron J1900 quad-core 64 bit CPU with a peak frequency of 2.0GHz. It supports multiple interfaces smoothly running, zero-delay, and no jamming at the same time. And I3 / i5 / i7 chips are available, 4G / 6G / 8G for running memory and 64G / 128G / 256G / 512G for hard disk SSD, 500g / 1T for mechanical hard disk for optional, All of this help the screen printing machine to achieve multi-color printing, automatic electric eye alignment, accurate and stable color registration.

In addition, Jawest industrial panel PC supports a wide range of working temperature of - 10 ℃ ~ + 60 ℃ and the customized working temperature reaches up to - 30 ℃ ~ + 70 ℃. Due to the features of the long-term operation of the screen printing machine, this panel PC also supports the automatic reset function. Besides, it helps the equipment realize the functions of setting printing quantity, automatic shutdown once without material, automatic shutdown with abnormal conditions and send alarm, which guarantees the stable operation of the equipment for a long time without obstacles and helps users improve the production efficiency.