The inspection AI robot of the data center, as the name suggests, its main job is to do patrol inspection in the data center. It is a common service robot that belongs to the patrol robot category. And it is similar to the inspection AI robot in power station, the inspection AI robot in railway, etc. In short, they are produced for a specific working environment to fill the disadvantages of labor.

Compared with the manual 24-hour inspection guard, the inspection of the AI robot is obviously more efficient and lower in cost. In reality, data center inspection is a complicated process. Humans can detect whether the circuit is running smoothly or not, whether the lighting equipment is abnormal, but it is difficult to detect the old and worn parts, loose and deformed parts, and indoor smoke, dust, etc., while the scientific inspection is the advantage of robots. Humans can determine the situation in the data center through existing and occurred situations, while AI robots can “foresee” problems in advance through more detailed observation and detection, and prevent problems before they occur.

The function of AI robots for inspection in the data center is to automatically detect and diagnose the equipment and environment in the data center through the combination of artificial intelligence and multi-sensor. Its work includes equipment detection and coding, data center environment detection, asset inventory, fault alarm, and personnel information management. The AI patrol robot of the data center is specially designed for the maintenance of the data center. In the environment of the data center, the robot needs to be "intelligent" like a human. It should know how to automatically plan the walking route, independently inspect and avoid obstacles, realize the real-time visualization and management of the machine room status, effectively improve the operation and maintenance efficiency and resource utilization rate, and improve the stability of the data center.

The application of industrial panel PC in the AI robot of the data center is embodied in the intelligent control terminal. According to the application requirements of the AI robot, as well as the expected settings of the staff to design it. It has the following responsibilities or requirements

1. Self-navigation and obstacle avoidance, automatic route planning, self-inspection.

2. Equipment testing, coding, indicator light, switch, instrument, screen display, surface temperature recognization.

3. Environmental detection: temperature and humidity, dust, smoke, noise, gas, wind speed, alarm.

4. Fault alarm, real-time fault diagnosis, fault warning, asset inventory, automatic statistics of equipment assets, dynamic update of asset list, personnel management.

5. Asset inventory, automatic statistics of equipment assets, dynamic update of the asset list.

6. Personnel management, IC/ID card reading, personnel information registration.

The existence of an industrial panel PC is a platform that required the operator to interact with the AI robot in the data center during the inspection. It needs to generate a feasibility report based on the inspection data, and finally display it in front of the operator; at the same time, it needs to perform personnel management and control responsibilities when it is responsible for security. Do the necessary registration and identification for the visitors. This requires the industrial panel PC to have its own operating system connected to the AI robot, capable of processing complex data and adding special module RFID readers, built-in microphones, cameras, .etc.

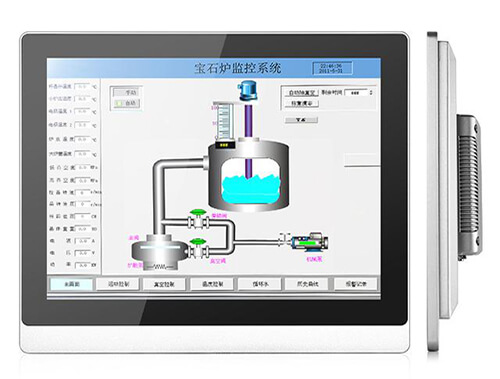

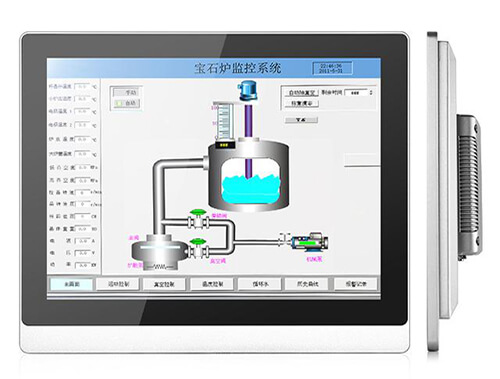

The Jawest industrial panel PC is available in silver and gun colors. Its industrial quality can meet the normal operation of the data center under high electromagnetic and high electrostatic interference environments. It is designed with die-cast aluminum alloy housing, IP65 dustproof and waterproof. Industrial aesthetic design, the overall shape is simple and smooth, which meets the needs of artificial intelligence robots. Its powerful performance guarantees 7X24 hours of uninterrupted, efficient, and stable operation in harsh environments.

In addition, Jawest industrial tablet PCs are compatible with 99% of industry software in the market. Modules and configuration upgrades can be customized according to actual needs, such as RFID card reader, face recognition, microphone, etc.

The performance parameters of the Jawest industrial tablet PC

1. High-precision aluminum alloy die-casting, anti-radiation structure design, and anti-electromagnetic interference due to their science internal structure design.

2. Independent developed of X86-based industrial-grade motherboards, built-with Celeron J1900 quad-core, (Core series upgradable), fast running speed, instant storage.

3. 24*7 hours uninterrupted high efficient and stable operation to meet the needs of inspection and security.

4. A variety of preset interfaces can be effectively transmitted and imported, and various modules can be customized to meet application requirements.

The inspection AI robot specially designed for data center has high reliability and adaptability to the special environment of the data center. Uninterrupted patrol inspections are based on scientific analysis. Take preventive measures before they happen, this is a potential market, and also have huge development space for industrial tablet PCs.