Manipulator is a kind of automatic operation device which can imitate some movement functions of hand and arm, and is used to grasp and carry objects or operation tools according to fixed procedures. The feature is that it can complete all kinds of expected jobs by programming. It has the advantages of both human and mechanical handset in construction and performance.

Manipulator is the earliest industrial robot and also the earliest modern robot. It can replace human's heavy labor to realize the mechanization and automation of production, and can operate in harsh environment to protect personal safety. Therefore, it is widely used in mechanical manufacturing, metallurgy, electronics, light industry, atomic energy, modern agricultural and other departments.

At present, the development of artificial intelligence is increasing at the rate of 9% annually, especially in manipulator. It is reported that the existence of industrial robots in the future will affect 400-800 million jobs of human beings.

As the "brain" of robot, the emergence of industrial mini PC, with embedded installation, will affect the evolution of various AI robots.

Industrial mini PC, also known as industrial mainframe, industrial box PC or industrial embedded computer. It has basic characteristics similar to computer, but it will be more stable in performance than computer in professional field. Based on the X86 framework, the industrial embedded computer provides a safe and stable operation platform for the manipulator, taking into account the hardware, software and manipulator programming.

At present, Jawest industrial mini PCs have been used in multiple application and fileds, such as sorting system in logistics, factory manufacturing automation, food & bevarage processing and so on. Its principle is to measure the three-dimensional coordinates of the workpiece, guide the robot to act take and place the workpiece; accurately locate the position of X, Y, Z coordinate position of the workpiece, provides the manipulator with two-dimensional or three-dimensional grabbing; no complex mechanical fixed design is required; provide the reliability of the automatic machinery; the incoming materials can be positioned and grabbed without arrangement or placement.

Jawest industrial mini PC features:

CPU: Intel Core CPU i3 / i5 / i7

Cooling system: Fanless for heat-dissipation

Memory: 2GB DDR4, Max. 8GB

Hard disk: 32GB SSD (64G~512G optional, HDD: 500G~1T)

USB: USB2.0, USB3.0

COM: COM*1/2 (default with RS232, 422/485 optional)

Dual display: VGA + HDMI

Audio: Audio I/O

WIFI/BT: Available

NIC chip: Onboard 1*Realtek RTL811E Gigabit network card (optional RJ45 * 2-6)

Power supply: input voltage 12V DC (aviation plug input)

System supporting: Windows 7 / Windows 8 / windows 10 / Linux

Working environment: -10 ℃ ~ 60 ℃ (14 ~ 140 ℉) (wide temperature optional)

Storage temperature: -20℃ ~ 70 ℃ (- 4 ~ 158 ° f)

Dimension: 379 (L) × 300 (W) × 63.5 (H) mm

Color: Black

Material: Aluminum alloy

Customer Case:

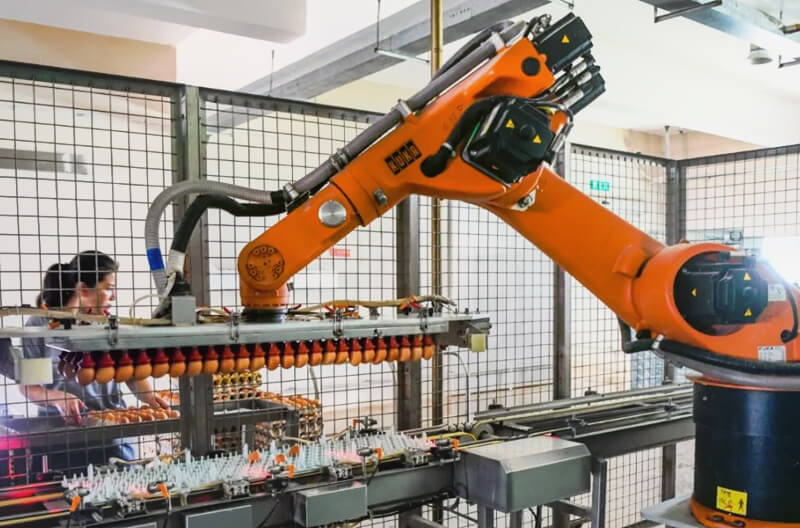

Our customer works on poultry industry, the industrial mini PC is installed in the intelligent manipulator to collect excellent fertilized eggs and enters the next incubation process.

Besides, Jawest industrial Android all in one tablet PC is used in the inspection robot.

There are three layers of shelves on both sides of the chicken house, the inspection robot moves slowly along the route set by the staff from the middle lane. Through the high-definition camera on the rack, the robot collects data in real time and monitors the activity of chickens.

According to the staff, inspection robot can reduce the biological risk of contact between human and poultry, and at the same time, it can sense the temperature, humidity, light and harmful gases of the chicken house in a mobile and multi-directional way in real time, so as to predict the epidemic situation of poultry as early as possible.

If an outbreak is found, the farmer uses his mobile phone to turn on the "smart veterinarian" and describes the symptoms of the chicken with words, pictures and voice. Within six hours, the APP analyzed "Prescriptions" through a large database, and then pushed them to the mobile phones of the farmers.

Industrial embedded computers are widely used in the following applications:

1. Aviation Information: Airport dynamic information display, query, monitoring management system, etc.

2. On board application: on board computer, on-board media broadcast, on-board field instruments and equipment, etc.

3. Special application: special environment electronic equipment, low radiation anti electromagnetic interference equipment, rugged computer, etc.

4. Mechanical equipment: reflow welding, wave soldering, spectrophotometer, spark machine, textile machinery, packaging machinery, binding machine, hexagram loading machine, etc.

5. Financial system: ATM, POS, lottery machine, entertainment equipment, self-service query terminal, etc.

6. Smart transportation: highway toll, traffic light monitoring, automatic overspeed capture, etc.

7. Video monitoring: building hard disk video, bank monitoring, coal mining underground video monitoring, bus video system, etc.